Manhattan’s Pennsylvania Station fills few New Yorkers with civic pride. A jumble of narrow train platforms and low-ceilinged, poorly signposted passageways shoehorned into the basement of Madison Square Garden, the complex crowds more than 200,000 New Jersey and Long Island commuters every weekday onto its narrow platforms and into its undersize waiting areas. Countless civic leaders have called for Penn Station’s aesthetic improvement. In 2013, when Madison Square Garden’s lease was up for renewal, then–Manhattan borough president Scott Stringer called for the Garden to be moved. The National Civic Art Society wants the old neoclassical Penn Station rebuilt exactly as it stood from 1910 until 1963, when the Pennsylvania Railroad demolished it in a desperate attempt to stave off bankruptcy. Another analyst has even suggested demolishing stadium and station alike, leaving only a row of platforms in a nine-acre hole. In any case, Amtrak plans to move its waiting and ticketing areas to Moynihan Station, a $1.6 billion conversion of a post office one block to the west.

More pressing than the station’s aesthetic drawbacks are its operational ones. Penn Station’s ill-maintained tracks are already being used to maximum capacity, and even slight disruptions to them can have crippling effects. When the station was partially closed in summer 2017 for emergency track and switch repairs, dozens of rush-hour trains had to be canceled or diverted to outlying stations, where commuters crammed onto subways and buses to Manhattan. Local press termed the situation the “summer of hell.” Penn Station also lies under a sword of Damocles. In 2012, Hurricane Sandy drove salt water into the century-old tunnels that carry the two-track connection from Penn to New Jersey, damaging their concrete lining and corroding electrical circuits. Any time in the next several years, one of the tunnels could experience a catastrophic electrical failure, or even collapse. Nothing has been done to repair the damage: fixing one of the tunnels would require shutting it down for months, cutting the station’s capacity by three-quarters. Amtrak, which owns Penn Station, hopes that it can build a relief tunnel before the current ones break.

In fact, such relief tunnels were almost constructed years ago. In 2003, NJ Transit proposed three Penn Station expansion plans, each estimated at slightly more than $3 billion. In 2008, NJ Transit chose a final plan in which two new tunnels led to six new terminal tracks in an annex to the station’s north. The budget by then had reached $8.6 billion. Construction on the New Jersey end of the tunnels had just begun in 2010, when New Jersey governor Chris Christie canceled the project, citing further cost overruns.

A year later, however, Amtrak and the Port Authority of New York and New Jersey proposed a similar project, with seven new terminal tracks to the south of the station rather than six to the north. They bundled the new tunnels and repairs to the old tunnels with bridge replacement and other track improvements in New Jersey, calling the combined project “Gateway.” Amtrak estimates that the new project will cost $29.1 billion, including $11.1 billion for the new tunnels and $7 billion for the Penn Station expansion. Any other city would consider such costs obscene.

In May 2011, an Israeli mathematician named Alon Levy, then just out of the doctoral program at Columbia, compiled the costs of 19 rail tunnels in the United States, Europe, South Korea, and Japan. He posted the list on Pedestrian Observations, a blog about what he modestly called “a side interest in urbanism and mass transit that is entirely unrelated to my work,” which was read by a dedicated group of his fellow hobbyists. In Japan and continental Europe, Levy found, tunnels usually cost between $200 million and $450 million per mile; the most expensive, the North–South Line in Amsterdam, still cost only $660 million per mile, more than twice its original budget. Spain, Italy, and South Korea were especially economical, building tunnels for less than $250 million per mile. (Since 2011, U.S. inflation has increased these numbers by about 12 percent.)

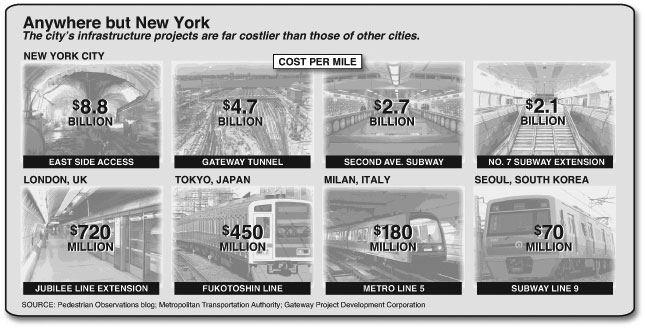

Every tunnel in the United Kingdom or the United States, though, was more expensive than every tunnel in continental Europe or Asia. And the three most expensive were all in New York City: the Number 7 subway extension ($2.1 billion per mile, despite “an unusually sparse station spacing”), the Second Avenue subway ($2.7 billion, by Levy’s reckoning, but closer to $2.4 billion in final cost), and, at more than $6.4 billion per mile, the East Side Access tunneling project from Long Island to Grand Central. Since 2011, cost estimates have risen even higher. The MTA now estimates East Side Access’s cost at $11.1 billion—or about $8.8 billion per mile, under Levy’s reckoning of the project’s length. A New York Times investigation found an MTA filing with federal regulators that gave an even higher cost: $12 billion, including budget items excluded from the MTA’s public statements, but not including the latest cost escalations. (See “Fifteen Stories Under,” Autumn 2015.) (Levy’s figures consider only new tunnels used in revenue service. Lower costs per mile reported elsewhere include train storage tracks in the length of the Number 7 extension and a preexisting two-deck river tunnel, the top deck of which currently carries the F subway train, in the length of East Side Access.)

Levy’s list drew attention to a neglected subject. Later in 2011, at a conference on infrastructure, Manhattan borough president Stringer cited Levy’s comparison of the London Underground’s Jubilee Line extension, which cost a high-by-world-standards $720 million per mile, with the Number 7 subway extension and Second Avenue subway in New York, which were three to four times costlier. Stringer identified New York’s excessive costs as a severe threat to the city’s prosperity.

Indeed, more difficult water crossings in Japan and Europe have cost far less than Gateway. For example, the Seikan Tunnel, built between 1971 and 1988 to carry trains between the Japanese islands Honshu and Hokkaido, runs 33.5 miles, 14.5 of them underwater, and cost 538.4 billion yen, or about $6.7 billion with Japanese inflation and present exchange rates. The Øresund Bridge connects Copenhagen, Denmark, to Malmö, Sweden, by means of a 4.9-mile bridge and a 2.5-mile tunnel joined on an artificial island. (A bridge the whole way would have blocked runway approaches at Copenhagen’s airport.) The link, carrying a two-track railway and a four-lane motorway, required the cooperation of two national governments with different currencies and languages, and cost 19.8 billion Danish kroner at 2000 price levels, or $4.3 billion with Danish inflation and present exchange rates. (Connecting roads and railways on land added 10.5 billion kroner.) The 2.3-mile Gateway tunnel is far simpler than the Seikan Tunnel and Øresund Bridge, but its $11 billion projected cost ($4.7 billion per mile) could pay for both of them together.

The rest of the United States is scarcely better than New York. Boston’s Green Line extension, at ground level in a preexisting freight-rail trench, will cost $2.3 billion for 4.3 miles, or $530 million per mile, even after the design was simplified to reduce costs. This would pay for a subway in continental Europe. In Washington, the second phase of the Silver Line, entirely aboveground, will cost $5.8 billion for 11.5 miles, or $500 million per mile. And on the West Coast, a one-station, 4.6-mile suburban extension of Bay Area Rapid Transit, all at ground level in a preexisting right-of-way except for a one-mile tunnel, cost $790 million, or $170 million per mile. Another almost-complete BART extension in the same right-of-way, with only two stations, will cost $2.3 billion for ten miles, enough for a Spanish or an Italian subway. By contrast, Vancouver’s Canada Line, which was built two-fifths underground in a dense urban area and boasts more than one station per mile, cost only $130 million per mile—and, by world standards, Canadian construction is not cheap.

Apologists for New York sometimes claim that the city’s preexisting infrastructure, geology, and high land values make construction difficult. But these difficulties exist in greater measure in other cities with lower costs. European tunneling projects routinely encounter medieval and Roman-era archaeological sites, and Los Angeles is extending its Purple Line subway through the La Brea Tar Pits, full of Ice Age fossils, for just $720 million per mile, costly by world standards but cheap for the United States. Similarly, Japan has high urban land values, large earthquake zones, and stronger protections against eminent domain than the United States, but much lower construction costs.

Some of the expense problem is the fault of the American legal sytem. The United States, like the United Kingdom and its other former colonies, has a common-law system that uses lawsuits to resolve disputes between the government and landowners or contractors. This has made recent construction projects in London, Dublin, Delhi, Dhaka, Vancouver, Hong Kong, and Singapore more expensive than the world average, though not nearly as expensive as New York’s. In an address to the Irish Parliament, Manuel Melis Maynar, CEO of the Madrid Metro, supported this view when he blamed the expense of the proposed Dublin Metro on Irish common law, which he called “very complex,” compared with Spanish law.

Bad contracting processes in many American cities also play a role; Levy has elsewhere noted that the cost overruns on Boston’s Green Line were incurred by a particular contractor and substantially reduced after the contractor was fired, and that several expensive projects in California have used the contractor Tutor Perini, which tends to submit implausibly low bids. (Tutor Perini has also built several components of East Side Access.)

But several factors make recent projects in New York especially unmanageable. One factor is the sandhogs’ union, which monopolizes public-sector underground construction. According to the New York Times, the sandhogs, who negotiate their contracts with private contractors rather than the public agencies that foot the bill, command $111 per hour in wages and benefits, with quadruple wages for weekend overtime. Tunnel workers elsewhere earn far less. For example, unionized tunnel miners in the Detroit metropolitan area earn $22.91 per hour in base pay, $39.32 including benefits; in Northern California, as expensive a place to live as New York, they make $36.12 in base pay, $59.88 including benefits.

Worse, sandhogs and other construction unions insist on overstaffing projects. The Berlin-based consultant Torsten Hahm says that a tunnel-boring machine (TBM) ordinarily needs seven workers; in Germany, such a worker would be paid about $38 in wages and benefits per hour. But a December 2017 investigation by Brian Rosenthal of the New York Times has shed more light on the overstaffing practices of New York’s MTA. For example, Rosenthal says that one tunneling contractor from California counted “25 or 26 people,” about three times what he thought was usual, working on a TBM during the extension of the Number 7 subway line, and quoted a third-party report that “underground construction employs approximately four times the number of personnel as in similar jobs in Asia, Australia, or Europe.” An internal MTA accountant even found that 200 of the 900 underground workers on East Side Access were superfluous: they were being paid full wages, even though officials could not discern their work duties, if any.

And for all this overstaffing, New York gets a much slower pace of work than it should. Hahm estimates that a 4.1-mile underwater tunnel in a typical geological environment, about 75 percent longer than Gateway, should take about three and a quarter years to build, including preparatory construction. The actual tunnel-boring should take 24 workers—seven belowground and five aboveground in each direction—two years to complete, at an unambitious pace of 50 feet per workday. Altogether, Gateway will take eight years.

Another part of the high costs lies in New York’s penny-wise but pound-foolish contracting. New York State procurement law usually requires that contracts be awarded to the lowest-bidding firm that passes a minimal check of “responsibility.” The Regional Plan Association has noted that this procedure encourages shoddy or inexperienced firms to submit implausibly low bids, ultimately costing the MTA far more in cost overruns and emergency repairs.

For competent contractors, the MTA provides a frustrating work environment. Levy has noted that to avoid being swindled by bad contractors with lowballed bids, the MTA writes contracts in overexacting detail. According to one person who has worked on several MTA projects, the MTA has also imposed two unusual conditions on past projects: requiring contractors to assume the financial risks created by unforeseen geological difficulties, forcing them to raise their bids to cover any contingency; and dictating a maximum salary for its consultants, with the result that the engineers legally liable for many projects earn less than some of their construction workers. Many competent contractors find this atmosphere intolerable and refuse to bid for MTA projects, reducing competition—the recent Number 7 extension, for example, had only one bidder.

The firms that do work with the MTA, however, enjoy a comfortable revolving-door relationship with its leaders, who may be reluctant to negotiate harshly with a possible future employer. Rosenthal found that at least 18 of 25 MTA agency presidents who had left the firm in the previous two decades became consultants or were hired by MTA contractors. Many former MTA managers went to work for WSP USA, a large American engineering firm that designed both East Side Access and the Second Avenue subway. And since Rosenthal’s report, Michael Horodiceanu, former CEO of MTA Capital Construction, has joined the board of East Side Access contractor Tutor Perini.

Gateway may not suffer from all these problems in the same measure. The project is being led by Amtrak, a federal agency, not the MTA. And Gateway’s cost estimates may increase or decrease as engineering and design work proceed. (A spokesman for the Gateway Project Development Corporation, a consortium that oversees the project, notes that the estimates were preliminary and would change when more about the design and contracting was known.) But the present estimates assuredly indicate something seriously wrong.

Even at reasonable construction costs, Gateway would still be too expensive, thanks to its planners’ neglect of a half-century of innovations and best practices developed overseas. In European and Japanese cities, population growth and the increasing expense of urban land forced transportation operators to economize, streamlining organization and investing heavily in new technology and electronics. In America, by contrast, fractured transit agencies waste billions of dollars on obsolete operational practices and infighting.

German-speaking transportation planners have a maxim: Organisation vor Elektronik vor Beton, or “Organization before electronics before concrete.” They mean that inefficiencies in a transportation system should be fixed first by improving coordination among different agencies, then by upgrading electronics systems, and only then by heavy construction. Visitors to Berlin can see this maxim in effect. The Verkehrsverbund Berlin–Brandenburg (VBB), a corporation owned jointly by 20 state and local governments, coordinates public transportation over 11,794 square miles in Berlin and the surrounding region. The 38 public and private operators that VBB oversees use a completely unified fare system: the same tickets that work on buses, ferries, and subways also work on longer-distance regional trains, and fares depend only on the route traveled, not on the mode of transportation. Transferring from one operator’s lines to another, unlike transferring from New York’s subway to the commuter rail or PATH, does not require paying twice. Such feats of organization are hardly unique. In Basel, Switzerland, the regional rail network, the S-Bahn, crosses into French and German territory and is operated jointly by all three nations’ national rail companies. And in Japan, holders of any of ten interoperable fare cards issued by regional railways can use them on virtually every urban train in the nation.

European and Japanese cities have also moved away from the old commuter-rail pattern of running trains from the suburbs to center-city terminal stations during the morning rush hour and leaving them there until the evening. Such an approach requires operational gymnastics or large trainyards on expensive center-city land. Instead, they have focused on building tunnels between the old downtown terminals, allowing trains to provide unbroken service from one side of the city to another and serve several stops in the city center—“through-running,” as it is called. The prototypical modern through-running project is the Réseau Express Régional (RER) in Paris, which opened in 1977 and connects regional railroads into north–south and east–west lines by means of two new tunnels under Paris. London’s Crossrail, a new east–west line with 26 miles of new tunnels, will similarly facilitate travel across London and relieve the overburdened Underground network. Tokyo’s two subways, the Metro and Toei Subway, even coordinate with other train operators to allow their suburban trains through the center-city tunnels. Some American cities have also moved toward through-running. Philadelphia’s Center City Tunnel, which opened in 1984 at the instigation of the Serbian-born University of Pennsylvania professor Vukan Vuchic, has enabled regional trains to make several stops in the center city and serve an inbound and an outbound line on the same trip. Los Angeles also plans to reconfigure its Union Station for through-running.

Through-running projects not only facilitate travel across downtowns but also improve operational efficiency. Passenger circulation is better when trains no longer discharge all their passengers at one terminal station, and trains stopping at a through station can continue ahead instead of reversing onto the outbound track and blocking other trains. (U.S. federal regulations requiring brake tests at every turnaround make reversals even more inefficient.) Busy through-running stations can therefore handle far more passengers with less infrastructure than Penn Station’s 11 platforms and 21 tracks. Châtelet–Les Halles on the Paris RER, for example, handles more travelers than Penn Station, with four platforms and seven tracks; the aboveground portion of Tokyo’s Shinjuku station, the world’s busiest, handles more than three times Penn Station’s ridership on eight platforms and 16 tracks. As through-stations need fewer tracks than terminal stations, they can give more space to passenger platforms, especially valuable in stations with narrow platforms obstructed by columns, such as Penn Station.

The disorganization in the United States, by contrast, severely worsens operations. For example, NJ Transit and the LIRR use different ticketing systems, and their ticket machines, even at Penn Station, cannot even sell each other’s tickets, making it impossible to pay for a trip from New Jersey to Long Island all at once. And every railroad has a separate passenger concourse and waiting area; Amtrak gives itself the largest passenger waiting area, even though it has the lowest passenger volume, exacerbating crowding for commuters.

This lack of cooperation among agencies, even the MTA’s own subsidiaries, has driven up the costs and diminished the benefits of several projects. The MTA has recently been focusing on East Side Access, a project that will give the Long Island Rail Road access to Grand Central. (See “Fifteen Stories Under,” Autumn 2015.) Grand Central has more tracks than any train station in the world, but rather than building a simple connection to the existing tracks and trusting that a future through-running plan would solve capacity problems, the MTA excavated a new deep-level cavern, unconnected to the existing tracks, exclusively for the LIRR. Much of the project’s world-record cost comes from this aspect. A 2013 report by the New York State Comptroller found that, of East Side Access’s then-estimated $8.8 billion cost, the cavern accounted for $1.9 billion, almost triple its initial estimate. (The cavern’s cost has since escalated to $2.3 billion.) The cavern was originally justified, in fact, as a cost-saving measure: by building so far underground, the MTA would avoid the need to reinforce the foundations of buildings along Park Avenue. But as costs escalated, the original plan stayed in place. One former MTA manager said that the choice of a cavern was partially motivated by Metro-North’s hostility to any plan that would allow problems on another railroad to harm its own operations.

Even today, Metro-North and the LIRR remain uncooperative. Metro-North wants to use the Penn Station slots freed by East Side Access to run trains from the New Haven Line to Penn Station, serving a neglected area of the Bronx. Long Island politicians oppose the project, and the former chairman of the MTA felt the need to assure Long Island residents that, in addition to their extra Grand Central trains, they would see no reduction in Penn Station trains.

The refusal to consider through-running has inflated Gateway’s prices. A large component of Gateway’s price tag is Penn South, the seven-track annex whose construction would require razing an entire block south of the current station. The real-estate acquisition alone would cost close to $1 billion. Gateway’s planning documents acknowledge that without some improvement to Penn Station itself, a new tunnel would make Penn’s operations more resilient to tunnel failure but would not allow any more rush-hour trains. But Penn South is not the best improvement to make. A focus on through-running rather than adding tracks would deliver a far superior improvement for much lower cost.

In fact, independent agencies have proposed several through-running plans. NJ Transit even considered one in its initial study for the ARC (Access to the Region’s Core) project, Gateway’s predecessor: “Alternative G” would have built a one-mile tunnel connecting Penn Station and Grand Central, instead of adding terminal tracks to Penn. Even at New York’s tunneling costs, the $7 billion price of Penn South could easily pay for such a tunnel. NJ Transit rejected this idea on the grounds that it would face problems with building around skyscraper foundations and create less new capacity than the other options. But the argument about capacity assumed that the new tunnel would be used not for true through-running but only to allow NJ Transit trains to terminate at Grand Central and Metro-North trains to terminate at Penn Station. This would redistribute Penn Station’s and Grand Central’s capacity woes but not eliminate them. Despite years of requests from local activists, NJ Transit has not released the full major investment study in which it justified the elimination of Alternative G.

New York’s transportation establishment will have no incentive to reduce prices to world standards as long as it can demand quintuple the world standard and get away with it. Gateway should be reduced to the minimum scope necessary to avoid a catastrophe. Larry Gould, a transit consultant for the urban-planning firm NelsonNygaard, has suggested one possibility: build only one tunnel, not two, for 60 percent to 65 percent of the expense of two tunnels, and then close the old tunnels, one at a time, for rehabilitation. All other capital-expansion projects except the most trivial should be put on hold until the region’s agencies credibly commit to a set of reforms.

Some of these reforms are straightforward, if politically unpalatable. If employing workers other than the sandhogs is politically inconceivable, the MTA and Amtrak should offer the sandhogs and their contractors a stark choice: work at staffing levels appropriate to a modern city, or have no public works projects be built at all. Given this choice, the sandhogs may find themselves willing to compromise. New York’s regional railroads should prioritize interoperability over expansion, and, if necessary, they should be dissolved as corporate entities and merged into one organization with unified management. The loss of an independent Long Island Rail Road may upset some politicians who enjoy having some fragment of the region’s transportation system under their control, but even they might be won over by the improved service that an integrated system could offer.

Other reforms will require a more extensive investigation into state and federal procurement practices. In March, the federal Government Accountability Office announced that it would investigate subway construction costs throughout the United States and other developed nations, publishing its findings before year-end. In the meantime, measures to improve transparency for all government contracts could help. Many of the MTA’s contracts can be obtained only by a long and uncertain Freedom of Information Law request; others, such as its contractors' labor contracts, are entirely barred from public view. It is hard to imagine that this furtiveness with taxpayer money has a legitimate purpose. New York State should require its agencies to publish all their contracts in full.

New York’s most fundamental problem, though, is a particular kind of provincialism. Too many New Yorkers are accustomed to seeing their residence as the greatest city not just in the United States but also in the world, one that has nothing to learn from other places. But the challenges of urban governance are, at bottom, everywhere the same, and New York’s private-sector prosperity cannot cover for its complacent civil service forever. Perhaps Scott Stringer, back in 2011, put it best: as long as New York tolerated infrastructure prices several times greater than the world standard, he said, “we cannot build a twenty-first-century city.”

Research for this article was supported by the Brunie Fund for New York Journalism.

Top Photo: The staggering price tag for plans to increase rail access into New York represents a threat to the region’s economic competitiveness. (PHILIP MONTGOMERY/THE NEW YORK TIMES)